Our company specializes in the production of precision dies for screws and nuts, with a special focus on carbide nut die technology. We provide reliable and high performance solutions to meet the requirements of the fastener industry.

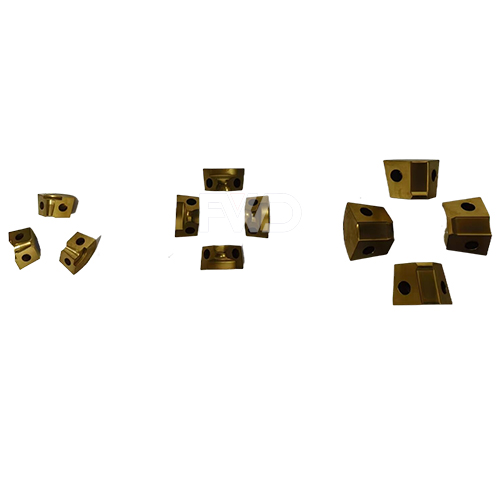

Carbide Nut Dies

High Wear Resistance: The carbide alloy construction provides outstanding resistance against wear, maintaining performance over extended usage.

Consistent Product Quality: Carbide Nut Die ensures uniform product quality, meeting stringent standards with every use.

Reduced Downtime: Its robust construction minimizes downtime, contributing to increased productivity in manufacturing processes.

Versatility in Nut Forming: Ideal for nut forming applications, Carbide Nut Die offers versatility in shaping a variety of nut designs with precision.

Adaptable to Various Materials: Accommodates different materials, ensuring flexibility in production for various industrial requirements.

Switch Components: Applied in the manufacturing of switch components, contributing to the reliability and durability of electronic switches.

Terminal Production: Utilized for shaping terminals in electronic devices, Carbide Nut Dies enhance the precision and longevity of electrical connections.

Circuit Board Fasteners: The dies play a crucial role in forming fasteners for circuit boards, ensuring stability and structural integrity.

Sensor Housings: Applied in shaping components like sensor housings, contributing to the accuracy and effectiveness of electronic sensors.

Microelectronics Manufacturing: Carbide Nut Dies find application in the production of small-scale electronic components, supporting the microelectronics industry.

Fuse Manufacturing: Essential in forming components for fuses, ensuring the reliability of electrical protection devices.

Battery Terminal Production: Applied in the manufacturing of battery terminals, ensuring secure connections in electronic devices.

Electronic Enclosures: Utilized for shaping components of electronic enclosures, enhancing the overall structural integrity and reliability of electronic equipment.

Advantages of Carbide Nut Dies

Our Carbide Nut Dies undergo a meticulous manufacturing process that embraces cutting-edge techniques to ensure precision and durability. Leveraging advanced CNC technology and an ERP system, we achieve intricate designs and strict tolerances required for various screw head shapes.

The CNC technology enables us to translate complex designs into reality, ensuring that each die meets the exact specifications for nut production. The integration of an ERP system streamlines the production process, enhancing efficiency and accuracy in design implementation.

Post-production, our Quality Control department meticulously examines every stage to minimize the defect rate. This thorough inspection guarantees that each Carbide Nut Die leaving our facility adheres to the highest quality standards.

Excellent abrasion resistance: Due to its high hardness, the carbide nut mold can maintain good abrasion resistance in high frequency use, which greatly extends the service life of the mold.

Good heat resistance: Carbide material can maintain stable performance in high temperature environment, not easy to be deformed or damaged due to high temperature.

High precision: Carbide nut molds can produce nuts with precise size and smooth surface to meet the high precision requirements in industrial production.

FAQ of Carbide Nut Dies

Parameter

| Carbide Nut Dies Product Information | |

| Product Name | Carbide Nut Die |

| Brand Name | Fuwangda |

| Place of Origin | Kunshan, Jiangsu, China |

| Specification | Customized on Request |

| Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

| Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

| Standard | DIN ANSI BS JIS |

| Tolerance | ±0.002mm |

| Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

| Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

| Hardness | Depends on material(HRC60~94) |

| Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

| Application | Machinery Parts and Molds |

| Material for Core of Carbide Nut Dies | ||||||

| Grade | WC+Other | Co | Grain Size | Density | Hardness | TRS |

| (±0.5%) | (±0.5%) | (g/cm³) | (HRA)±0.5 | (N/mm²) | ||

| KG5 | 88 | 12 | Medium | 14.31 | 88.3 | 340 |

| KG6 | 86 | 14 | Medium | 14.12 | 87.3 | 320 |

| EA65 | 82 | 18 | Coarse | 13.75 | 85 | 300 |

| EA90 | 76 | 24 | Coarse | 13.22 | 82.8 | 270 |

| ST6 | 85 | 15 | Coarse | 13.8 | 86 | 270 |

| ST7 | 80 | 20 | Coarse | 13.4 | 85.3 | 270 |

| VA80 | 80 | 20 | Coarse | 13.58 | 84 | 280 |

| VA90 | 78 | 22 | Coarse | 13.39 | 82.5 | 240 |

| VA95 | 75 | 25 | Coarse | 13.12 | 81.5 | 220 |

| Material for Casing of Carbide Nut Dies | |||

| Material | Hardness (HRC) | Features | Applications |

| H13 | 59-61 | H13 is a chromium molybdenum hot work steel with exceptional hot hardness and abrasion resistance, general hardness, and toughness. | Used for extrusion dies, forging dies, stamping tools, etc. |

| SKD11 | 58-61 | SKD11 tool steel has good wear resistance and size ability after heat treatment. | Used for tensile dies, cold extrusion dies, first punch holder, etc. |

| SKD61 | 43-53 | SKD61 steel is a high-grade die casting die. It has heat shock resistance, heat deformation resistance, heat fatigue resistance. | Used for heat work dies, cold heading dies, second punch holders. |

Order Process