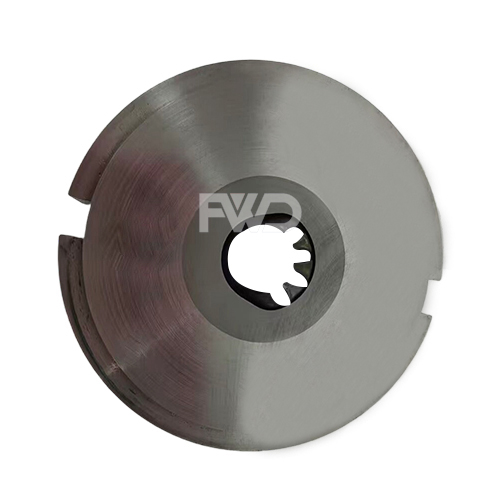

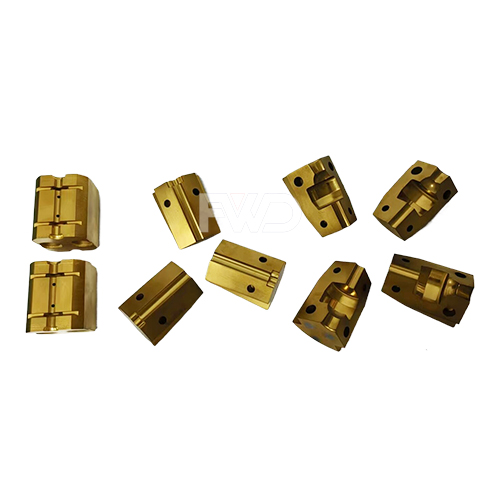

Cold Forging Dies

2. Precision Engineering: Cold Forging Dies are engineered with high precision to produce parts with tight tolerances and complex geometries. The dies are often designed using advanced CAD/CAM software, ensuring that every detail is meticulously planned and executed.

3. Surface Treatment: To enhance the durability and lifespan of the dies, various surface treatments are applied, such as nitriding, PVD coating, or carburizing. These treatments increase the surface hardness and resistance to wear and corrosion, allowing the dies to maintain their performance over extended production runs.

4. Customizability: Cold forging dies can be customized according to specific production requirements. Manufacturers can design dies to produce parts in various shapes and sizes, from simple bolts and nuts to intricate gears and shafts. Custom dies are developed to meet the exact specifications of the client’s product, ensuring optimal performance and efficiency in production.

Applications of Cold Forging Dies

1. Automotive Industry: Manufacturing high-strength fasteners, gears, and shafts for vehicles.

2. Aerospace Industry: Producing lightweight and durable components such as brackets, fittings, and connectors.

3. Construction Industry: Creating high-strength bolts, nuts, and other fasteners for construction projects.

4. Electronics Industry: Fabricating precision connectors and small metal components used in electronic devices.

2. Cost-Effective Production: Cold forging dies enable mass production of metal components with minimal material waste. The process is highly efficient, reducing production costs while maintaining high quality.

3. Improved Surface Finish: Components produced using cold forging dies often have a superior surface finish, reducing the need for additional machining or finishing processes.

4. Environmental Benefits: Cold forging is an energy-efficient process that requires less energy compared to hot forging, making it a more environmentally friendly manufacturing method.

Quality Assurance

Manufacturers of cold forging dies adhere to strict quality control standards to ensure that the dies meet the highest performance and durability requirements. This includes rigorous testing for hardness, dimensional accuracy, and resistance to wear and fatigue.

FAQ of Cold Forging Dies

Order Process