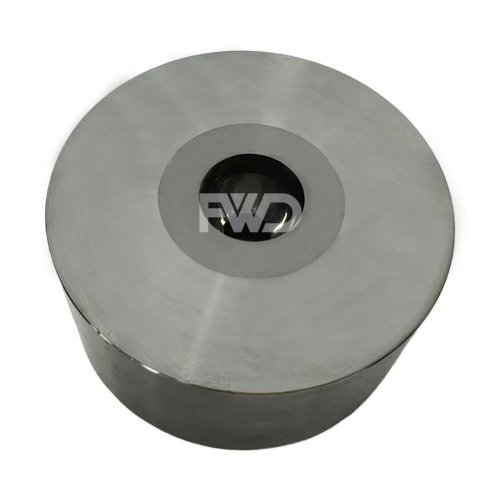

Hard Alloy Molds

Hard Alloy Mold is manufactured through powder metallurgy technology, and its preparation process includes steps such as raw material mixing, pressing and forming, sintering, processing, and coating. Among them, compression molding is the process of mixing Tungsten Carbide powder with an appropriate amount of binder to produce the desired shape and size; Sintering is the process of heating the pressed material to a high temperature, causing the binder to evaporate and forming a metallurgical bond between tungsten carbide particles; Processing is the process of cutting, grinding, and polishing sintered materials to achieve the required size and accuracy; Coating is used to improve the wear resistance and heat resistance of cutting tools. Usually, a hard coating such as TiN, TiCN, etc. is applied to the surface of the tool.

The main components of Hard Alloy Mold are tungsten carbide (WC) and cobalt (Co), among which tungsten carbide has high hardness and wear resistance, while cobalt can improve the toughness and strength of the material. In addition, tungsten carbide molds also contain a certain amount of elements such as titanium (Ti) and chromium (Cr), which can improve the material’s heat resistance and oxidation resistance.

2. Wear Resistance: The material’s superior wear resistance ensures a long service life, reducing the frequency of die replacements and maintenance.

3. Heat Resistance: Hard alloy molds can withstand high temperatures, making them suitable for processes involving heat or thermal stress.

4. Dimensional Accuracy: The precision of tungsten carbide allows for the production of dies with tight tolerances and accurate dimensions, ensuring consistent quality in the final products.

2. Molding: The powder mixture is pressed into the shape of the die using high-pressure molds. This step forms the initial shape of the die but does not yet achieve the final hardness.

3. Sintering: The molded die is heated in a sintering furnace at extremely high temperatures (typically around 1400-1600°C). This process causes the binder to melt and bind the tungsten carbide particles together, resulting in a solid, dense, and hard material.

4. Machining and Finishing: After sintering, the die is machined to precise dimensions and surface finishes. This step may involve grinding, polishing, and other processes to achieve the final specifications.

5. Testing and Quality Control: The finished dies are tested for quality and performance, including hardness, wear resistance, and dimensional accuracy. Any defects are identified and corrected to ensure that the die meets the required standards.

1. Stamping and Forging: In automotive and aerospace industries, hard alloy molds are used for stamping and forging metal parts with high precision and durability.

2. Extrusion: In the plastics and rubber industries, hard alloy molds are employed to shape and form materials during the extrusion process.

3. Molding: Hard alloy molds are used in injection molding and compression molding processes to produce high-quality plastic and metal parts.

4. Wire Drawing: In the wire and cable industry, hard alloy molds are used to draw and shape wire, ensuring consistent diameter and quality.

FAQ of Hard Alloy Mold

Order Process