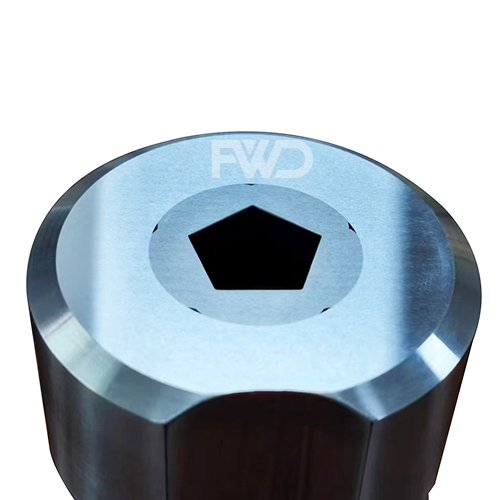

Hot Heading Dies

The process of hot heading is commonly used to form metal parts from wire, bars, or billets, where the metal is heated to a temperature that makes it easier to shape. Hot heading dies are typically made from high-performance tool steels or other heat-resistant materials to ensure they can endure the harsh conditions of the process.

Precision Engineering: Hot heading dies are designed to create highly precise shapes with tight tolerances, ensuring consistency across multiple parts.

Heat Resistance: Given the high temperatures involved in the hot heading process, these dies are made from heat-resistant materials, such as high-carbon tool steels, which maintain their strength and hardness even at elevated temperatures.

Durability: Since the process involves intense pressure and heat, hot heading dies are built to be durable and long-lasting. The die materials and design are optimized to minimize wear and tear over time.

Customization: Hot heading dies can be custom-designed to accommodate specific part shapes, sizes, and materials, ensuring optimal performance for the unique needs of different industries.

Tool Steels: Tool steels, such as AISI H13, D2, and other high-carbon alloys, are commonly used for hot heading dies due to their excellent resistance to wear, high toughness, and ability to maintain hardness at high temperatures.

High-Speed Steels (HSS): High-speed steels offer superior heat resistance and can maintain their cutting and forming capabilities even at higher operational temperatures.

Carbide: For extremely high-precision applications, carbide dies are sometimes used due to their exceptional hardness and wear resistance. These materials can withstand the most demanding conditions.

Applications Of Hot Heading Dies

Automotive Industry: In the automotive sector, hot heading is used to produce components such as bolts, nuts, washers, and fasteners. These parts require high strength and durability to withstand the demanding conditions in vehicles, such as vibrations and high temperatures.

Aerospace: Aerospace manufacturers use hot heading dies to create critical components such as turbine blades, fasteners, and structural parts. The high precision and material strength of these parts are essential for ensuring the safety and performance of aircraft.

Construction and Heavy Machinery: Parts such as shafts, pins, and gears used in construction equipment and machinery are often formed using hot heading dies. These components need to withstand extreme stresses and wear during operation.

Industrial Equipment: Hot heading dies are also used in the production of components for industrial machinery, where high-strength parts are necessary to ensure the longevity and efficiency of machines.

Heating the Metal: The metal material, often in the form of billets or wire, is heated to a high temperature, typically between 900°C to 1,200°C, depending on the material being used.

Forming the Metal: The heated material is then placed in the hot heading die. The male die applies pressure to the material, forcing it into the female die cavity, which shapes the metal into the desired form.

Cooling and Ejection: After the part is formed, it is cooled, and the shaped metal is ejected from the die. The part may undergo additional processes, such as trimming, finishing, or heat treatment, to achieve the final specifications.

FAQ of Hot Heading Dies

Order Process