Main Dies

Common steel types include:

D2 Steel: Known for its hardness and wear resistance, suitable for cutting and forming operations.

H13 Steel: Offers high toughness and heat resistance, often used in hot working applications.

Carbide: Extremely hard and wear-resistant, used in high-precision and high-wear applications.

2. Material Selection: Choosing appropriate materials based on the application and required properties.

3. Machining: Initial shaping of the die using processes like milling, turning, and grinding.

4. Heat Treatment: Processes such as quenching and tempering to enhance material properties like hardness and toughness.

5. Finishing: Precision machining, including EDM (Electrical Discharge Machining) and polishing, to achieve the final dimensions and surface finish.

6. Assembly and Testing: Assembling die components and conducting trial runs to ensure proper functionality and performance.

Key Features of Main Dies

2. Precision Threading: They are designed to cut or form threads with high precision, ensuring that the threaded components fit perfectly with mating parts, such as nuts or threaded holes. This precision is crucial for ensuring the reliability and safety of the assembled components.

3. Versatility: Main dies come in various sizes and thread pitches, accommodating a wide range of threading requirements. They can produce both standard and custom thread profiles, depending on the application.

4. Heat Treatment: Many main dies undergo heat treatment processes to enhance their hardness and durability, making them suitable for use in demanding manufacturing environments.

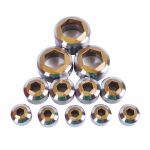

5. Different Configurations: Main dies can be found in different shapes and configurations, including round dies, hexagonal dies, and adjustable dies. Each type serves specific threading needs, with adjustable dies allowing for minor adjustments in thread diameter.

2. Aerospace Industry: Essential for creating high-precision threaded parts that meet the stringent safety and performance standards required in aircraft and spacecraft.

3. Machinery and Equipment: Applied in the production of threaded components for various types of industrial machinery, ensuring robust and reliable connections.

4. Construction: Used in creating threaded rods and bolts that are used in building frameworks, bridges, and other structural elements.

5. Repair and Maintenance: Handy in repair shops and maintenance facilities for re-threading or creating new threads on worn-out or damaged fasteners.

FAQ of Main Dies

Order Process