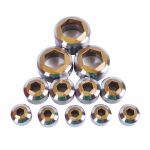

Punch & Dies

Structure customization: The structure of the punching die can also be customized. Depending on the processing needs of the product, different punching die structures can be designed to meet different processing requirements. For example, some punching dies may need to punch holes in multiple locations at the same time, while others may need to achieve different depths of punching.

Automation Customization: As automation technology continues to evolve, punching dies can be used with automated equipment for more efficient processing. By customizing automated punching systems, functions such as automated feeding, positioning and punching can be automated to further increase productivity.

Advantages of Punch & Dies

Accuracy: Punching dies are usually manufactured with very high precision to ensure that the size, location and shape of the punched hole meets the design requirements. This accuracy is critical for products that require high precision holes.

Durability: Punching dies are usually made of abrasion- and corrosion-resistant materials to maintain stable performance under harsh operating conditions. Meanwhile, the structural design of the punching die is optimized to withstand greater impact and pressure, ensuring stable work over a long period of time.

Flexibility: The punching die can be customized according to different needs and is suitable for processing holes of various shapes, sizes and materials. In addition, the punching die can also be used in conjunction with other molds to achieve more complex processing needs.

Safety: Punching dies usually offer a high level of safety during operation. For example, some punching molds are equipped with safety protection devices that can prevent the operator from being injured during operation. In addition, the maintenance and repair of perforating dies is relatively simple and easy, which can reduce equipment failure rates and repair costs.

1. Cutting: Cutting sheet metal to a specific shape, such as to create metal sheets, washers, etc.

2. Punching: punching out holes in sheet metal, such as manufacturing bolt holes, vent holes, etc.

3. Forming: Forming metal sheets into specific curved or concave shapes by pressing, e.g., to make automobile body panels.

Manufacturing Processes of Punch Head Mold

Materials for Punch & Dies

To ensure durability and high precision, Punch & Dies are typically manufactured using high-strength materials such as high speed steel (HSS), carbon tool steel and carbide. These materials have excellent wear and impact resistance and can be used for long periods of time under high pressure and high temperature conditions.

Surface Finishes for Punch & Dies

To extend service life and improve performance, Punch & Dies often undergoes surface treatments such as nitriding, titanium plating, chrome plating, etc. These treatments increase the hardness and performance of the surface. These treatments increase surface hardness and corrosion resistance, reducing wear and improving durability.

FAQ of Punch & Dies

Order Process