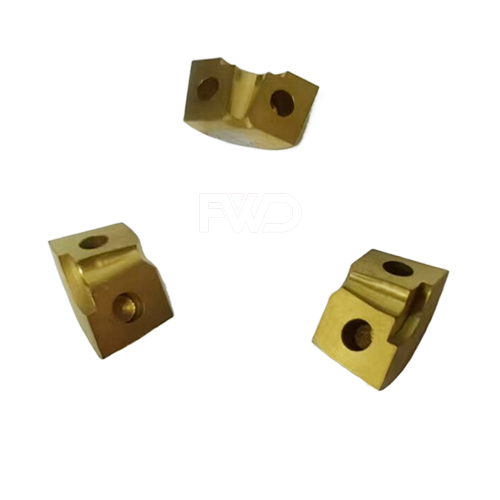

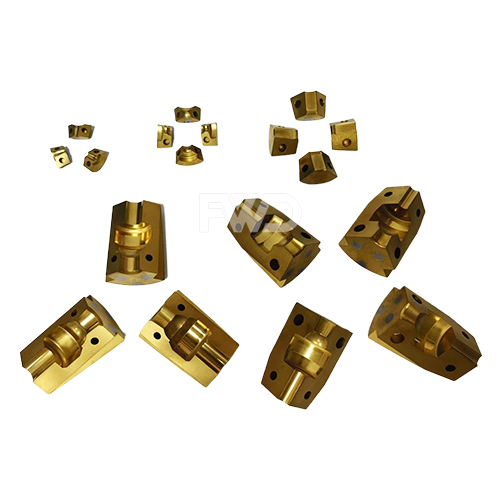

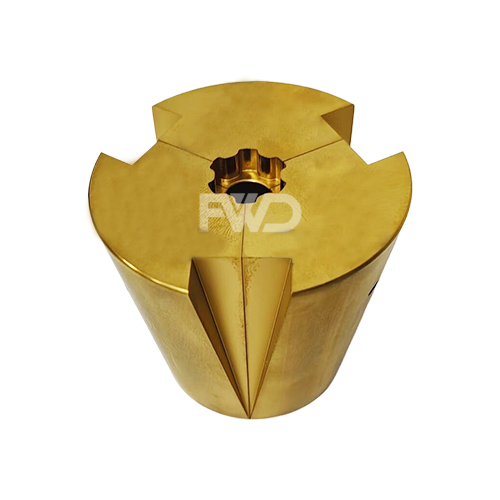

Three-Piece Collapsible Mold is a special mold used for injection molding, consisting of three parts: upper mold, lower mold and middle mold. This mold design allows a portion of the mold to be folded for easier release from the molded part. Typically used to produce parts with internal structures, such as holes or hollow parts. Its design can reduce damage to molded parts and improve production efficiency. Three-piece foldable molds are widely used in industries such as plastic products, medical devices, and electronic products.

Working Principle

Features

Reduce damage: The folding design of the mold can reduce damage to the molded parts during the removal process and protect the integrity and quality of the product.

Wide applicability: Suitable for the production of parts that require internal structures, such as holes or hollow parts, meeting the molding needs of complex products.

Improve efficiency: The folding design reduces the difficulty of taking molds, speeds up the use cycle of molds, and improves production efficiency and capacity.

Reduce costs: Reduce product damage and mold replacement times, reduce production costs reduce production costs and improve production efficiency.

Precise molding: The three-piece structure ensures the stability and accuracy of the mold, ensuring the accuracy and consistency of the molded parts.

High reliability: After optimized design and strict testing, the stability and reliability of the mold are ensured, and it performs well in long-term production.

Wide range of applications: Suitable for plastic products, medical equipment, electronic products and other industries, providing effective solutions for the production of various complex parts.

Maintenance and care

Checking wear and tear: Regularly check the parts of the mold, especially the wear and tear of the folding core, and replace the parts with serious wear and tear in time to ensure the normal use of the mold.

Lubrication: Regularly lubricate the movable parts of the mold to reduce friction and wear and prolong the service life of the mold.

Storage environment: The mold should be stored in a dry and ventilated environment to avoid moisture and corrosion and keep the performance of the mold stable.

Application Fields

Home Appliances: Many parts in home appliances have complex internal structures, such as the inner tubes of washing machines, air ducts of air conditioners, etc. Three-Piece Collapsible Mold can meet these needs.

Medical Devices: Medical devices often require high precision and complex shaped parts, Three-Piece Collapsible Mold can provide high quality molding solutions to meet strict medical standards.

Consumer Electronics: In the consumer electronics field, many products such as cell phone cases, laptop cases, etc. require parts with complex structures and high quality appearance, and Three-Piece Collapsible Mold can provide the ideal molding solution.

FAQ

Parameter

| Three-Piece Collapsible Mold Product Information | |

| Product Name | Three-Piece Collapsible Mold |

| Brand Name | Fuwangda |

| Place of Origin | Kunshan, Jiangsu, China |

| Specification | Customized on Request |

| Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

| Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

| Standard | DIN ANSI BS JIS |

| Tolerance | ±0.002mm |

| Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

| Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

| Hardness | Depends on material(HRC60~94) |

| Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

| Application | Machinery Parts and Molds |

| Material for Core of Three-Piece Collapsible Mold | ||||||

| Grade | WC+Other | Co | Grain Size | Density | Hardness | TRS |

| (±0.5%) | (±0.5%) | (g/cm³) | (HRA)±0.5 | (N/mm²) | ||

| KG5 | 88 | 12 | Medium | 14.31 | 88.3 | 340 |

| KG6 | 86 | 14 | Medium | 14.12 | 87.3 | 320 |

| EA65 | 82 | 18 | Coarse | 13.75 | 85 | 300 |

| EA90 | 76 | 24 | Coarse | 13.22 | 82.8 | 270 |

| ST6 | 85 | 15 | Coarse | 13.8 | 86 | 270 |

| ST7 | 80 | 20 | Coarse | 13.4 | 85.3 | 270 |

| VA80 | 80 | 20 | Coarse | 13.58 | 84 | 280 |

| VA90 | 78 | 22 | Coarse | 13.39 | 82.5 | 240 |

| VA95 | 75 | 25 | Coarse | 13.12 | 81.5 | 220 |

| Material for Casing of Three-Piece Collapsible Mold | |||

| Material | Hardness (HRC) | Features | Applications |

| SKD61 | 52-55 | SKD61 steel is a high-grade die casting die. It has heat shock resistance, heat deformation resistance, heat fatigue resistance. | Used for heat work dies, cold heading dies, second punch holders. |

| SKD11 | 58-60 | SKD11 tool steel has good wear resistance and size ability after heat treatment. | Used for tensile dies, cold extrusion dies, first punch holder, etc. |

| DC53 | 59-61 | DC53 steel is a high-performance cold work tool steel with excellent wear resistance, high hardness, and good toughness. It also offers superior edge retention and dimensional stability. | Used for cold heading dies, stamping dies, cutting tools, and other high-wear applications. |

| SKH-9 | 60-62 | SKH-9 is a high-speed tool steel with excellent wear resistance, high hardness, and good toughness. It maintains sharpness and strength even at high temperatures, making it ideal for high-performance cutting applications. | Used for drills, taps, reamers, cold heading dies, and other high-speed cutting tools. |

Order Process