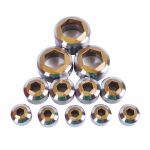

Tungsten Carbide Dies

Exceptional Hardness and Strength

Tungsten carbide, an alloy composed of tungsten and carbon, is renowned for its extraordinary hardness, ranking close to diamond on the Mohs scale. This property makes tungsten carbide dies highly resistant to deformation and abrasion, ensuring extended service life even in high-pressure manufacturing environments.

Superior Wear and Corrosion Resistance

Compared to traditional steel moulds, tungsten carbide dies offer enhanced wear resistance, significantly reducing tool wear and maintenance costs. They also exhibit excellent resistance to corrosion, making them suitable for harsh industrial environments where exposure to moisture, chemicals, and extreme temperatures is common.

High Precision and Dimensional Stability

Precision is a critical factor in fastener manufacturing. Tungsten carbide dies provide outstanding dimensional stability, ensuring consistent accuracy in the production of bolts, studs, screws, and nuts. This level of precision minimizes material waste and enhances product quality, leading to improved operational efficiency.

Cost-Effectiveness and Longevity

While the initial investment in tungsten carbide dies may be higher than conventional steel alternatives, their extended lifespan and reduced maintenance requirements lead to significant cost savings over time. Manufacturers benefit from fewer production interruptions and lower replacement costs, making tungsten carbide dies a smart long-term investment.

Applications of Tungsten Carbide Dies in Fastener Manufacturing

Cold Heading Dies – Used for shaping fasteners through high-pressure metal deformation.

Thread Rolling Dies – Essential for forming precise and durable screw threads.

Punch Dies – Employed in stamping and forming operations to create high-precision fastener heads.

Nut Forming Dies – Designed to manufacture nuts with tight tolerances and uniform dimensions.

Wire Drawing Dies – Utilized in shaping and reducing wire diameter before further processing.

Grade Selection

Different tungsten carbide grades are available to suit various manufacturing conditions. Choosing the right grade ensures optimal performance, balancing hardness and toughness based on production requirements.

Coating Options

Advanced coatings such as TiN (Titanium Nitride) or TiCN (Titanium Carbonitride) can enhance the performance of tungsten carbide dies by further increasing wear resistance and reducing friction.

Customization Capabilities

Many manufacturers offer customization options for tungsten carbide dies, allowing for tailored solutions that meet specific fastener production needs. Customization ensures improved efficiency and better alignment with production goals.

FAQ of Tungsten Carbide Dies

For premium-quality tungsten carbide dies designed for bolts, studs, screws, and nuts, partnering with a reliable supplier ensures access to superior materials and expert craftsmanship. Upgrade your fastener production process with tungsten carbide dies and experience the difference in durability and precision.

Order Process